- Home

- Technology

Technology

Revive and Reuse

Unlocking The Power Of Battery Regeneration

To ensure business continuity and near 100% uptime for the purpose of meeting customer demands or regulatory expectations, many businesses incorporate backup stationary power into their value chain. In the event of a power supply failure, the stationary power kicks in.

Most, if not all, stationary power comes in the form of fossil fuel generators, Uninterruptible Power Supply (UPS), and backup batteries. Where batteries are concerned, in particular lead acid batteries that are commonly used, they are often replaced way before their designed lifespan due to the typical usage patterns. Typically, the designed lifespan of batteries is up to 20 years. But the actual lifespan is really 2 to 10 years – only 30% to 50% of their designed lifespan.

What causes the short actual lifespan

This is mainly due to battery terminals’ sulfation during discharge. Battery terminals return to normal when you recharge it. However, the process is not 100% efficient as sulfate crystal remnants attach to the terminals, thickening crystals, and worsening battery capacity over multiple cycles of charging and discharging.

The sulfation build-up side effect is unavoidable, and after 3 to 4 years, it substantially accelerates. More energy is then needed for the entire process and the battery temperature rises, which reduces the battery life. Other factors also come into play such as the reduction of electrolytes, corrosion of the electrode plates, and the decline of active materials.

Effects

This incurs a huge cost for businesses that have to keep disposing and replacing these batteries. In terms of sustainability, this practice isn’t viable in the long run for both company and the environment. Cost goes up, and with the waste accumulated, the company is contributing to large carbon emissions which is harmful for the environment.

* The diagram above is based on standard practice.

The Solution

Battery Regeneration Technology

Our regeneration technology helps to recover and lengthen your battery lifespans, reducing the need to constantly replace old batteries with new ones. Through regeneration, battery sulfation dramatically reduces as lead sulfate crystals are efficiently dissolved into electrolyte, refreshing both terminals and electrolyte. This will allow the battery capacity to dramatically increase, which will be financially beneficial to the company and more sustainable to the environment.

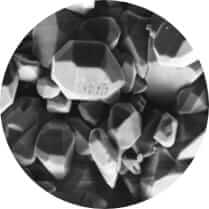

New Battery Status

New lead sponge battery plate.

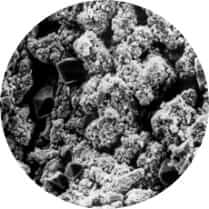

Degraded Battery Status

Battery plate has been coated by dense, hardened lead sulfate crystals. No active lead sponge is visible.

On Processing Regeneration

The size of lead sulfate crystals are decreasing. The lead sulfate crystals are decreasing and dissolved by our regeneration process.

Regenerated Battery Status

The final recovery of battery plate to active lead sponge.

Here’s A Closer Look At Our Regeneration Technology

- Patented 100% pure electrical signals treatment decomposes input electricity into non-invasive Shark Pulses

- Battery capacity is replenished with no alterations

- Inverter technology is also applied to ensure no heat or energy loss

- With smart control phase, voltage and current, these shark pulses effectively remove lead sulfates from electrode plates, making the electrodes and electrolyte pristine once more

- The battery can once again perform as good as new battery

Let's Work Together

Towards a better future with industry-recognised sustainability initiatives